Frequently Asked Questions

What is "2-point" KestrelCalTM calibration?

The "2-point" calibration method was developed exclusively by Catalina Scientific for use with the SE 200 echelle-type spectrograph built by Optomechanics Research.

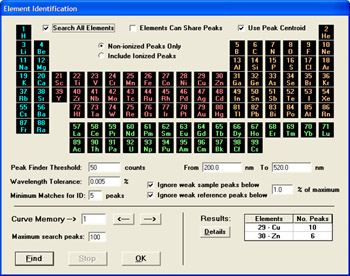

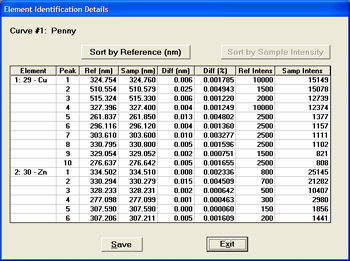

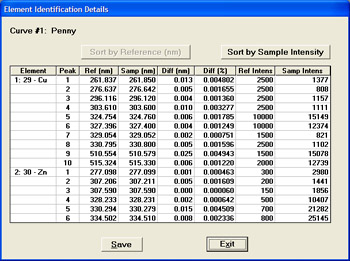

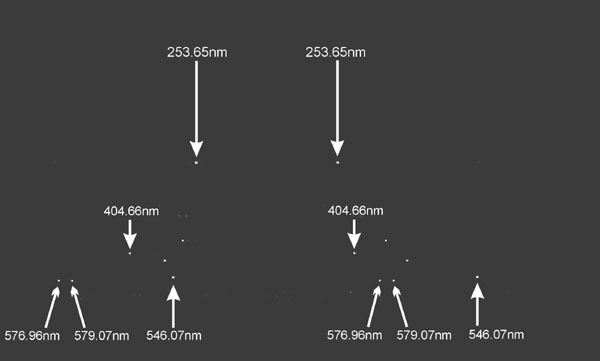

To calibrate an SE 200, an Hg image is first acquired and any two prominent Hg peaks are selected for the 2-point calibration. KestrelSpec has a Peak Finder tool for images to aid in determining the location of prominent peaks. Below is an example of an Hg echelle image with the prominent peaks labeled:

The X and Y coordinates of two prominent Hg peaks are entered in the calibration dialog box, which in this example are 546.074nm and 579.066nm for an SE 200 spectrograph:

The user then clicks on the Calibrate X Axis button and KestrelSpec calculates the calibration parameters that will be used in the creation of spectral curves from acquired images. Once the "2-point" procedure is successful, each acquired spectral curve will be accurately calibrated in either nm or Raman cm-1 units.

What is "3-point" KestrelCalTM calibration?

The "3-point" calibration method was developed exclusively by Catalina Scientific for use with the EMU-120/65 echelle spectrograph that we design and build.

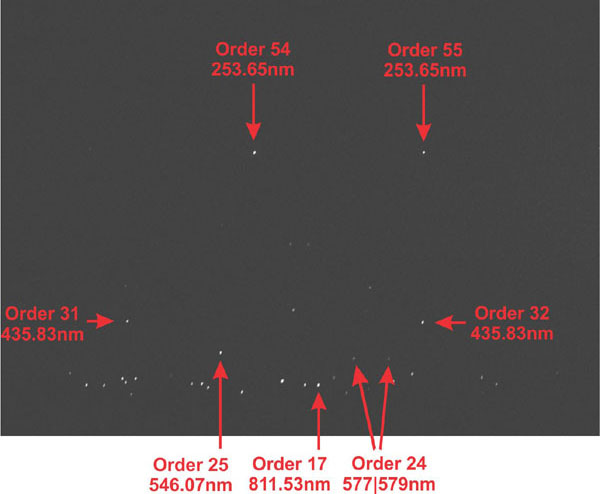

To calibrate the EMU-120/65 spectrograph, an Hg/Ar image is first acquired and three prominent Hg and Ar peaks are selected for the 3-point calibration. KestrelSpec has a Peak Finder tool for images to aid in determining the location of prominent peaks. Below is an example of an Hg/Ar echelle image acquired with the EMU-120/65 with the prominent peaks labeled:

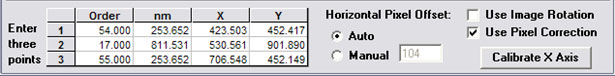

The X and Y coordinates of three prominent Hg and Ar peaks are entered in the calibration dialog box, which in this example are two Hg peaks at 253.652nm and an Ar peak at 811.531nm:

The user then clicks on the Calibrate X Axis button and KestrelSpec calculates the calibration parameters that will be used in the creation of spectral curves from acquired images. Once the "3-point" procedure is successful, each acquired spectral curve will be accurately calibrated in either nm or Raman cm-1 units.

What is KestrelTempTM temperature calibration?

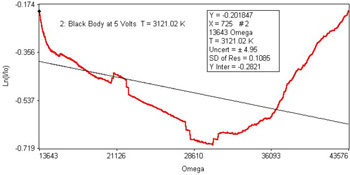

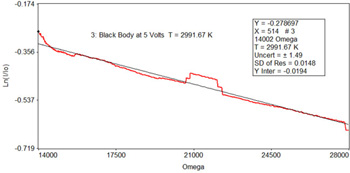

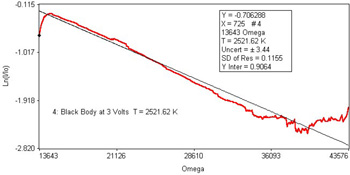

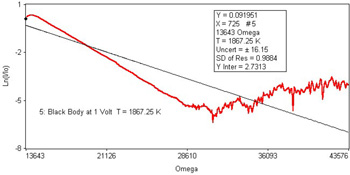

In the current version of the KestrelSpec software, there is an option to acquire and display spectral curves in Temperature Mode. KestrelTempTM is a method of calculating the unknown temperature of spectral data once a temperature reference curve, with a known temperature, has been defined. This known temperature reference curve and any unknown sample curve are then transformed by a proprietary algorithm to produce a linear function of relative intensity versus frequency (Omega). The temperature of the unknown source can then be calculated from the slope of this relationship between relative intensity and frequency. The software calculates a least squares fit to the function and determines the temperature of the unknown source including a 1 sigma error coefficient. The accuracy of the temperature calculation can be optimized by adjusting the spectral range over which the least squares fit is operating. The better the fit, the smaller the temperature error estimate.

In the sample temperature spectra below, a reference spectrum was acquired from 330nm to 1050nm using a black body source at 6 volts with a known temperature of 3200K. Three subsequent spectra of unknown temperature were then acquired covering the same 330nm to 1050nm range using the black body source at 5, 3 and 1 volts. The curves below show the relative intensity versus frequency and the calculated temperature and error estimate for each of the unknown samples:

| For more information, please contact us: |

Catalina Scientific 2555 North Coyote Drive, Suite 113 Tucson, AZ 85745 USA Phone: 520-571-8000 |

Entire site copyright © 1998-2025 , Catalina Scientific |